|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||

| The application of HIPRECO is very suitable for the processing of general hard cutting and machining materials, including atomic energy plant construction materials, aerospace construction materials and advanced energy producing plant construction materials. | ||||||||||||||||||||||||||||||||||||||||||||

| We would like to enhance the productivity of material cutting, machining and processing works at a stretch with accuracy and speed ・・・・ In order to satisfy the above requirements, it is prerequisite to adopt the spindle-through ; High Pressure Coolant (HPC). If not, there would be a great difference of productivity and accuracy between the use of HPC and no-use of HPC. |

||||||||||||||||||||||||||||||||||||||||||||

Features |

||||||||||||||||||||||||||||||||||||||||||||

| ① High-performance plunger pump is installed (Advanced tyoe high-pressure pump is used. Then a great deal of water discharge can be realized). | ||||||||||||||||||||||||||||||||||||||||||||

| As one of leading pump manufacturers in Japan, the manufacturer has manufactured high-pressure pumps provided with more than 7.0MPa pressure, by accumulating long-experienced know-how. As a matter of fact, the pump featured highly endurable and stabilized properties. U-HIPRECO-185 Type is a global standard type (cope with all waters used world widely). ※ SUS316 materials are used for pump wetted parts. | ||||||||||||||||||||||||||||||||||||||||||||

| ② High micro dust can be filtered by a precision type filter: | ||||||||||||||||||||||||||||||||||||||||||||

| Exclusively designed filter-less cyclon filter is used. When floating carbon dusts or micro particles are many, the Skimmer can recover such harmful matters. As a result, the abrasion of cutting tools can be protected. successfully (Option). | ||||||||||||||||||||||||||||||||||||||||||||

| ③ Motors can be controlled in proportion to the liquid flow rate loading. | ||||||||||||||||||||||||||||||||||||||||||||

| In proportion to the liquid discharge amount from the high-pressure pump, the motor speed can be controlled automatically. As a result, energy-saving and CO2 emission reduction from environmental areas can be made successfully. | ||||||||||||||||||||||||||||||||||||||||||||

| Proposal of High Pressure Coolant (HPC) unit according to a high-pressure coolant unit. | ||||||||||||||||||||||||||||||||||||||||||||

| Accompanied with the recent environmental variations, advanced requirements are required alongside by the industrial needs. |  |

|||||||||||||||||||||||||||||||||||||||||||

| ●Cost reduction ●Stabilization of quality ●Energy saving |

||||||||||||||||||||||||||||||||||||||||||||

| In order to satisfy the above requirements, we have developed an advanced spindle-through type High Pressure Coolant (HPC) unit. | ||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

| Merits obtained from the use of the HPC | ||||||||||||||||||||||||||||||||||||||||||||

| ●Elevation of cutting speed Improvement of production efficiency and elevation of productivity ●Reduction of cutting tool abrasion Elongation of cutting tool service life time and reduction of cutting tool costs ●Stabilization and elevation of quality accuracy ●Energy saving Control of output control in proportion to the flowing load ●Decrease of CO2 emission into the atmosphere by reduction of machining/processing time |

|

|||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

| Major specifications | ||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

| We have started to develop ultra-high-pressure pumps provided with 30 MPa pressure. As for the details of the above pumps, please consult with us. |

||||||||||||||||||||||||||||||||||||||||||||

| Dimension | ||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

| Experiments of High Pressure Coolant (HPC) conducted by using HIPRECO. | ||||||||||||||||||||||||||||||||||||||||||||

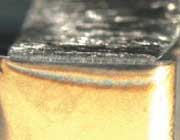

| Test materials of “Inconel 718 43HRc” were experimentally cut and machined for 3 minutes. Then chips thus obtained were examined mainly for their shape. | ||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

| The test materials of “Inconel 718 43HRc” were experimentally cut and machined by applying 150br and 300br of coolant pressure, and then, cutting chips were obtained. | ||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

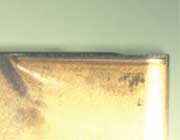

| Abrasion loss of a cutting tool tip elapsed by the normal use of Titan (Ti-6AI-4V) material by applying normal pressure and by applying HPC. | ||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

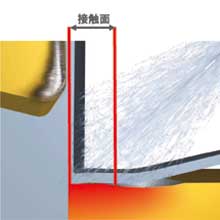

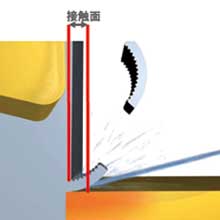

| Towards the new and advanced cutting concept by using the High Pressure Coolant (HPC) | ||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

| ハイプレッシャークーラント(HPC)技術に関する詳しい資料をご用意しております。 ご希望のお客様はダウンロードして下さい。新たな旋削概念をご提案いたします。 |

||||||||||||||||||||||||||||||||||||||||||||

| ●Download the document. | ||||||||||||||||||||||||||||||||||||||||||||